‘For every kilo of petha produced, 400 grams of waste adds to Agra’s pollution woes’

As per the findings of a recent study, Agra’s famous petha industry generates 17,800 kilograms of solid waste per day. The waste is dumped in public spaces which raises the risk of outbreak of diseases like cholera, malaria, dengue and diarrhoea. Details here.

According to the study, due to improper collection, transportation and processing facilities most of this petha waste is dumped or disposed of on open plots and grounds or roads. Photo: Creative Commons

The magnificence of the Taj Mahal is undoubtedly the first image that strikes most of the people whenever Agra is mentioned but what is often overlooked about the city is the unhygienic disposal of waste that is prevalent in its congested lanes and bylanes. What adds to the city’s notorious waste disposal woes is its petha industry.

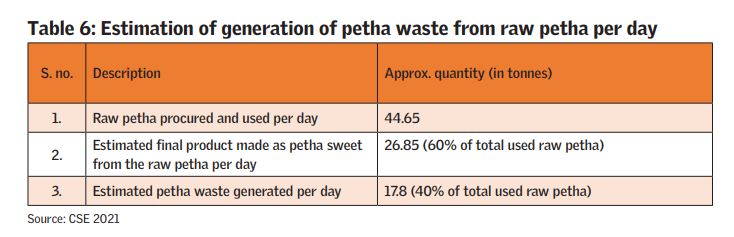

Rivalling the Taj Mahal in being the historic city’s identity for centuries, petha is a soft, translucent candy made from winter melons (ash gourd) but a study titled Petha Waste Management in Agra City – An Assessment which was conducted by New Delhi-based Centre for Science and Environment in April, 2021, reveals that 17,800 kilograms of solid waste is generated by the petha industry in the city in a single day.

Also Read: India’s waste management systems unfit to address the silent pandemic of antimicrobial resistance

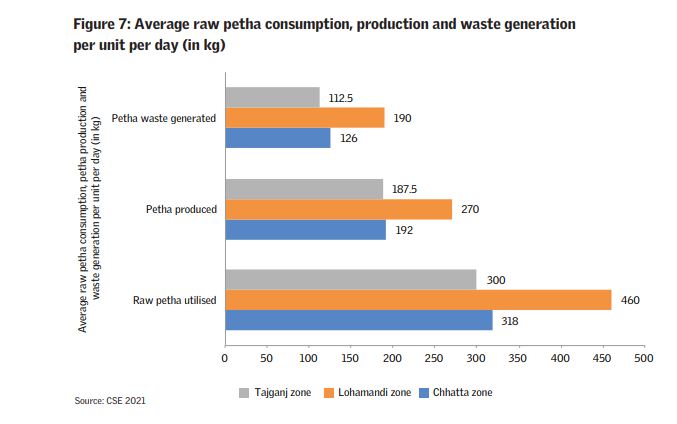

The study informs that 44,650 kilograms of raw petha is procured for producing the sweetmeat on a daily basis and the final product produced in a day weighs 26,850 kilograms.

“Therefore about 0.4 kg of petha waste is generated for every 1 kg raw petha used to make petha,” the study found.

Also Read: World Toilet Day: ‘Livelihood a bigger concern for sanitation workers than personal safety’

According to the study, due to improper collection, transportation and processing facilities most of this petha waste is dumped or disposed of on open plots and grounds or roads.

“The petha waste purifies and emits a foul odour, is an unpleasant sight and attracts flies and mosquitoes, leading to diseases such as cholera, diarrhoea, malaria and dengue,” it stated.

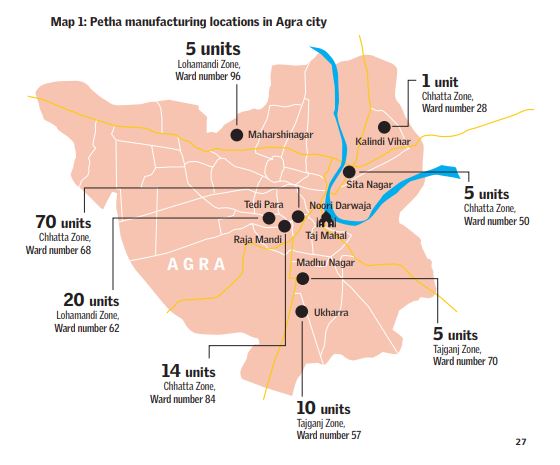

To study the process of petha making, current management practices and disposal of waste generated from petha making and to estimate the quantity of waste, 30 petha makers in eight locations under three administrative zones were covered — Chhatta, Lohamandi and Tajganj.

Also Read: ‘90% diarrhoea deaths in India due to lack of safe drinking water and basic sanitation facilities’

Challenges for treating petha waste

The study mentioned that storing large volumes of ash gourd peel, which forms almost 40 per cent of the total petha waste, is a challenge for petha makers.

“ Large metal or plastic vessels are used for storing the waste. The size of the vessel depends on the scale of production. For example, every 100 kg of raw petha produces about 40 kg of petha waste, which is completely organic and biodegradable,” the study stated. During the study, vessels full of ash gourd peel were found on the roadside, with stray cattle feeding from it.

“Field-level observation suggests that the current practice of storing and placement of petha waste prior to disposal needs substantial improvement,” it mentioned.

Also Read: Open dumping and burning of mixed biomedical waste raises a stink in Sitapur

It is informed that about 54 per cent petha makers that were interviewed during the study claimed that their waste—which is basically vegetable peels—is collected by cattle farms in Agra city. “However, no field-level evidence of the collection mechanism was observed,” the study noted.

The study added that despite the significant pollution footprints from petha waste since the 1990s, no dedicated facility has been planned or installed.

“While the Agra Municipal Corporation has recognized the management of petha waste as a major challenge, field-level arrangements to manage the waste were absent,” it stated.

As a result, petha waste has been dealt with like other municipal solid waste generated within the city.

“Processing and treatment is currently limited to options exercised by the petha makers, such as sending waste to cattle farms as feed for animals, giving the waste to AMC’s collection services for monthly charges, getting rid of the waste through the informal collectors and dumping it erratically in the nearest dhalaos or bins,” it noted.

“In absence of a proper collection, transportation and treatment facilities, the problem has barely been addressed. Petha peel and seeds extracted from petha pulp have a good market if avenues to use them are properly planned and executed,” it added.

Solutions for safe disposal of petha waste

According to the study, there are about 200 cattle farms around the city that require 40,000–48,000 kg of cattle feed every day (assuming the daily diet of cattle is around 25–30 kgs).

“Therefore systematic channelization of the petha waste could be a good solution to the problem of petha waste in Agra. Such system would require planned fleet movement designed to factor in the total quantity of petha waste generated every day,” it suggested.

The study also mentioned as a suggestion that petha seeds can be sold in local markets at different rates depending on whether they are raw or processed. “Wet seeds are sold for about Rs 15 per kg while the dried seeds are sold for as much as Rs 60 per kilogram,” claimed the study.

Some suggestions from the study

- Creating a geotagged inventory of petha makers in Agra: To effectively plan for sustainable management of petha waste, it is of paramount importance to create an inventory of petha makers in the city. By geotagging the locations and providing trade licenses to the petha makers, ANN can keep a tab on the changing number of petha making units in Agra.

- Getting the petha makers registered as bulk waste generators: According to Solid Waste Management Rules, 2016, establishments producing more than 100 kg of waste on a daily basis shall be considered BWGs (bulk waste generators) and they shall be responsible for in situ treatment of the organic waste. As revealed during the study, all the petha makers are BWGs as they produce more than 100 kg of organic waste on a daily basis. Hence Agra Nagar Nigam should serve them notice to get themselves registered as BWGs.

- Alternative use of raw petha waste for generation of food products: Raw petha has several health benefits. Once it is utilised for petha making, however, it is considered as waste by petha makers. Petha waste can also be used to make food products like pickles etc.